Key Takeaways:

- Neodymium, discovered in 1885, is a rare earth metal essential for powerful permanent magnets.

- Neodymium magnets (N52 grade) are over 100 times stronger than traditional ferrite magnets.

- These magnets are made from an alloy of neodymium, iron, and boron, allowing for high magnetic energy production.

- Applications range from wind turbines and MRI machines to consumer electronics and robotics.

- Neodymium magnets are popular in DIY projects, offering innovative solutions for design and organization.

- They enhance audio quality in high-end speakers and are critical in magnetic levitation technologies.

- Safety precautions are necessary due to potential injuries and risks to electronic devices when handling neodymium magnets.

- Proper storage techniques are essential for maintaining the strength and longevity of neodymium magnets.

- Future trends focus on improving magnetic properties, developing eco-friendly alternatives, and optimizing manufacturing processes.

- The automotive and renewable energy industries are benefiting significantly from the integration of neodymium magnets.

The Science Behind Neodymium Magnets: What Makes Them So Special?

The Origins of Neodymium: From Rare Earth to Everyday Use

Neodymium, an element with the atomic number 60, is classified as a rare earth metal and plays a crucial role in the manufacture of powerful permanent magnets. Initially discovered in 1885 by German chemist, Dr. Carl Auer von Welsbach, the metal remained relatively obscure until the 1980s when advancements in materials science brought it into the limelight. The emergence of neodymium magnets revolutionized various industries due to their unparalleled magnetic strength and compact size.

With applications spanning the realms of consumer electronics to medical devices, neodymium has transitioned from a laboratory curiosity to a staple in everyday technology. Today, neodymium magnets, particularly those of the N52 grade, offer a strength that is over 100 times greater than that of traditional ferrite magnets, thereby expanding their applicability, efficiency, and usability in numerous fields.

Magnetic Properties Explored: Why Neodymium is the Strongest

The profound strength of neodymium magnets primarily stems from their atomic structure and the properties of the materials used in their creation. These magnets are composed of an alloy of neodymium, iron, and boron (NdFeB). This unique combination facilitates a high magnetic energy product, measured in megagauss-oersteds (MGOe), enabling them to generate extraordinarily strong magnetic fields. The alignment of magnetic domains in neodymium, coupled with its optimal intrinsic coercivity — which refers to a material’s resistance to becoming demagnetized — makes it the strongest commercially available permanent magnet.

With applications in everything from wind turbine generators to magnetic resonance imaging (MRI) machines, understanding the intricacies of these properties allows one to appreciate how neodymium magnets can outperform traditional magnets by leaps and bounds.

How Neodymium Magnets Are Manufactured: A Peek into the Process

The manufacturing process of neodymium magnets is intricate and requires precision to ensure quality and performance meets the demands of modern applications. The journey begins with the careful extraction and refinement of neodymium, iron, and boron, typically sourced from mineral ores like monazite and bastnäsite. After initial extraction, the raw materials undergo several processing steps, including melting them together in a vacuum to form the alloy.

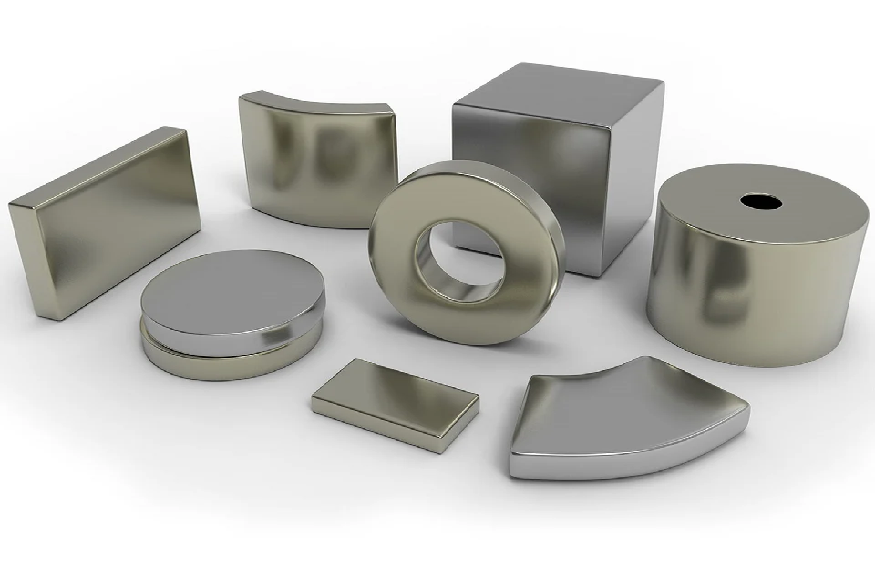

The subsequent stage involves the creation of a powder using a milling technique, which is essential for optimizing the magnetic properties. The powder is then compacted into molds, subjected to high temperatures (sintering), which induces crystal growth and enhances magnetic characteristics. This sintered piece is ground to precise dimensions, coated to prevent corrosion, and finally magnetized through exposure to a strong magnetic field, resulting in the robust neodymium magnets we encounter in everyday use.

Unleashing Versatility: Creative Uses of Neodymium Magnets

From Industrial Applications to DIY Projects: The Sky’s the Limit

The versatility of neodymium magnets is nothing short of astounding, showcasing their broad scope of applications across both industrial and consumer domains. In the industrial space, neodymium magnets are indispensable in various sectors, including automotive, aerospace, and manufacturing. They are employed in electric motors and generators, where their superior magnetic strength contributes to energy efficiency and performance.

Additionally, in the realm of robotics, neodymium magnets facilitate efficient movement and positioning of components, enhancing operational precision. In a more creative context, DIY enthusiasts utilize neodymium magnets for a plethora of projects. From building custom furniture and innovative storage solutions to crafting magnetic closures for bags and clothing, the applications are limited only by one’s imagination. Using neodymium magnets can simplify complex tasks, streamline the organization of tools, and promote creative innovation. Their diminutive size paired with immense strength enables users to create sleek, modern designs that were previously unattainable with traditional magnetic options.

Innovative Gadgets and Gizmos Powered by Neodymium

Neodymium magnets are at the heart of countless innovative gadgets and devices, enhancing their functionality and performance. For example, in the world of audio technology, high-end speakers and headphones incorporate neodymium magnets for producing superior sound quality. The lightweight nature of these magnets offers the dual benefit of portability and ease of use without compromising on sound fidelity. Moreover, neodymium is leading the charge in cutting-edge technologies like magnetic levitation systems. These systems propel trains and vehicles without contact, reducing friction and wear while increasing efficiency and speed.

Furthermore, neodymium magnets are integral in computer hardware, most notably in hard disk drives where they are used in the actuator assemblies to move read/write heads with precision. The ubiquity of neodymium magnets in modern gadgets illustrates their importance in driving innovation and enhancing user experiences.

Neodymium in Art and Design: Enhancing Aesthetics with Strength

The intersection of art and technology is beautifully highlighted through the use of neodymium magnets in design and artistic expressions. Artists and designers have begun to harness these powerful magnets to create interactive installations and sculptures that engage viewers on multiple levels. Magnetic sculptures, often designed to seem weightless or in motion, challenge the viewer’s perception and invite them to engage physically with the artwork.

Moreover, interior designers have leveraged the strength and discreet profile of neodymium magnets for innovative fixture solutions. From seamless mountings for picture frames to magnetic curtain rods, these applications reduce the need for visible hardware, resulting in clean lines and a minimalist aesthetic. The ability to detach and rearrange elements effortlessly makes design adaptable and dynamic, inviting creativity and responsiveness from both artists and users alike. As the boundaries of art and technology converge, neodymium magnets emerge as silent yet powerful enablers of transformative design.

Safety and Handling of Neodymium Magnets: What You Need to Know

Dealing with the Power: Risks of High-Strength Magnets

While the incredible strength of neodymium magnets offers numerous advantages, it also presents certain risks that must be carefully managed. Their powerful magnetic forces can easily cause injury due to pinching or crushing when fingers or body parts become trapped between two magnets or a magnet and a metal surface. This can lead to serious injury, especially in cases where larger magnets are involved. In addition to physical injuries, the impact of neodymium magnets on personal electronic devices should not be dismissed either.

They can interfere with the functioning of pacemakers, credit cards, smartphones, and other sensitive electronics. Thus, it is essential to adhere to recommended guidelines for handling and storage. Awareness of these hazards is vital in environments where neodymium magnets are frequently employed, making proper training and caution key components in their use.

Proper Storage Techniques to Keep Your Magnets in Top Shape

To maintain the integrity and longevity of neodymium magnets, proper storage practices are imperative. When not in use, magnets should be stored in a manner that reduces the risk of damage or demagnetization. Keeping them in pairs or stacks with a protective spacer between each magnet is recommended to prevent them from clashing and breaking.

Additionally, they should be kept away from electronic components and devices to avoid interference. Store neodymium magnets in a cool, dry environment, as exposure to extreme temperatures and humidity can harm the magnet’s magnetic properties over time. Using magnetic storage containers specifically designed for neodymium magnets can help organize and protect them from environmental factors and physical damage. Following these storage techniques will ensure the magnets retain their strength and usability over time.

How to Protect Yourself and Your Electronics

To safely work with neodymium magnets, it is crucial to adopt a few practices that prioritize your safety and the protection of electronic devices. First and foremost, always handle neodymium magnets with care and avoid sudden movements that can cause them to snap together unexpectedly. Wearing protective gloves can help mitigate the risk of pinching injuries when handling larger magnets. When it comes to electronics, maintain a safe distance between neodymium magnets and devices that could be adversely affected by magnetic fields. Be aware of the proximity to devices like smartphones, tablets, and credit cards, as magnets can encode or erase data on magnetic strips.

For protection, utilize shielding measures such as aluminum foil when transporting or storing neodymium magnets near sensitive equipment. Educating oneself about the potential impacts of neodymium magnets on health and electronic devices can foster a safer and more responsible approach to handling these powerful tools.

Future Trends: The Next Frontier of Neodymium Magnet Technology

Advancements in Magnet Research: What Lies Ahead?

The field of magnet research is ripe with possibilities, especially as the demand for neodymium magnets continues to ascend in various sectors. Ongoing research is focused on enhancing the magnetic properties of neodymium magnets, exploring new composite materials, and creating magnets with improved thermal stability for industrial applications. The quest for lightweight yet powerful magnets is driving innovations that may lead to breakthroughs in the efficiency of energy systems, particularly in renewable energy sources where magnet strength plays a pivotal role in generation and conveyance.

Collaborative efforts are also underway among scientists and engineers to optimize the manufacturing processes, reducing costs and environmental impact while maintaining high-performance standards. The future looks bright as researchers unlock the potential for neodymium magnets to contribute to more sustainable practices in tech manufacturing, transportation, and energy sectors.

Eco-Friendly Alternatives: The Quest for Sustainable Magnet Solutions

With growing concerns regarding environmental sustainability and the ecological impact of mining rare earth elements, there is a pressing need to explore eco-friendly alternatives to traditional neodymium magnets. Research is being conducted into the development of magnets that can achieve similar strength without relying entirely on rare earth materials. Materials such as iron nitride and other ferromagnetic compounds are being investigated for their potential to create high-performance magnets with reduced environmental footprints.

Furthermore, the concept of recycling existing neodymium magnets also holds promise. By reclaiming neodymium from used electronic devices and magnetic systems, the amount of raw material required for new production can be dramatically reduced. This circular approach not only conserves valuable resources but can also reduce the carbon emissions associated with mining and processing rare earth metals. The pursuit of sustainable magnet solutions points towards a future where technological progress aligns harmoniously with environmental responsibility.

How Neodymium is Shaping Industries: A Look into Tomorrow

As neodymium magnets continue to evolve, they’re shaping the future of numerous industries in revolutionary ways. In the automotive sector, their role in electric vehicles is indispensable; enabling more efficient power motors and enhancing battery performance is critical for advancing transport technologies and reducing reliance on fossil fuels. The renewable energy industry also sees immense potential in neodymium magnets—wind turbines equipped with these magnets can achieve higher output efficiency, directly contributing to the global push for sustainable energy solutions.

As more industries integrate high-strength neodymium magnets in their designs and operations, the influence of this remarkable material will only continue to expand, paving the way for innovation across medicine, robotics, and consumer technologies. The journey of neodymium magnets from their rare earth origins to becoming a dominant force in industrial and everyday applications exemplifies the fascinating intersection of science and practicality. This ultimate guide not only sheds light on the remarkable qualities of neodymium magnets but also encourages a responsible approach to their handling and an understanding of their future potential in an ever-evolving technological landscape.

FAQ

Question: Can neodymium magnets be used in high-temperature environments? – Neodymium magnets typically lose their magnetism when exposed to high temperatures, so applications in elevated heat conditions require specially formulated magnets designed for such environments.

Question: How can I safely demagnetize a neodymium magnet? – Demagnetizing a neodymium magnet can be accomplished through exposure to a strong opposing magnetic field or applying heat, but it is important to approach this process with caution to avoid damage or unwanted hazards.

Question: Are there any health risks associated with handling neodymium magnets? – While there are no direct health risks from handling neodymium magnets, the physical injuries from pinching or crushing can occur if proper safety precautions are not taken, especially when dealing with larger magnets.

Question: How can I recycle old neodymium magnets? – Recycling neodymium magnets can be done through specialized recycling programs or facilities that accept rare earth elements, which can help reduce environmental impact and reclaim valuable materials.

Question: What should I avoid placing near neodymium magnets? – Sensitive electronic devices such as smartphones, tablets, credit cards, and pacemakers should be kept at a safe distance from neodymium magnets to prevent data loss or functional interference.

Question: How do I prevent neodymium magnets from losing their strength? – To maintain the strength of neodymium magnets, store them in a cool, dry place, avoid physical impacts, and keep them away from other strong magnetic fields or extreme environmental conditions.

Question: Can neodymium magnets be painted or coated? – Neodymium magnets can be coated with various materials to prevent corrosion or enhance aesthetics, but it is crucial to use compatible coatings that do not interfere with their magnetic properties.

Question: What is the lifespan of neodymium magnets? – Under proper handling and storage conditions, neodymium magnets can last for decades without significant loss of magnetism, but exposure to harsh conditions may shorten their lifespan.

Useful Resources

- Nature – Scientific Journal

- ScienceDirect – Research Articles

- American Physical Society – Physics Resources

- IOPscience – Institute of Physics

- TechTarget – Technology Topics

- Magnet Sales – Magnet Information

- RRUFF Project – Mineral Research

- NASA – Scientific Research and Innovations